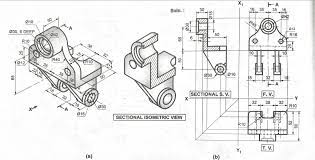

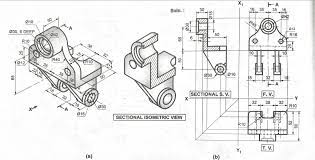

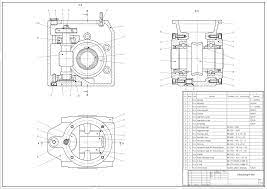

2D Drawing & 3D Model development from Reverse Engineering on sample & Technical Assistance

Tool / Die Development from 2D drawing & 3D Model

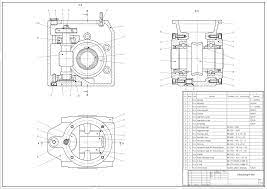

Tool / Die Inspection Report

Wax Sampling with Inspection Report

Mass Production with Machining Services

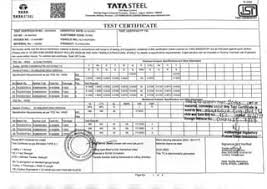

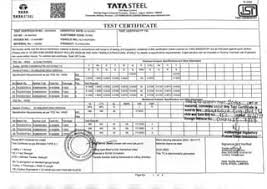

Chemical Testing like Spectro Analysis, PMI & Weight Analysis

Heat Treatment

Mechanical Testing like Tensile, Impact, Band, Hardness & etc Testing

Metallographic Testing like Micro & IGC Testing

NDT Testing like DPT, MPI, RT & UT

3.1 MTC & Prototype Report with Final Inspection Report

2D Drawing & 3D Model development from Reverse Engineering on sample & Technical Assistance

Tool / Die Development from 2D drawing & 3D Model

Tool / Die Inspection Report

Wax Sampling with Inspection Report

Mass Production with Machining Services

Chemical Testing like Spectro Analysis, PMI & Weight Analysis

Heat Treatment

Mechanical Testing like Tensile, Impact, Band, Hardness & etc Testing

Metallographic Testing like Micro & IGC Testing

NDT Testing like DPT, MPI, RT & UT

3.1 MTC & Prototype Report with Final Inspection Report

Single Piece Size – 700mm x 800mm (Max)

Single Piece Size – 700mm x 800mm (Max)  Single20 Grams to 200 Kg. for Steel & 20 Grams To 40 Kg for Non – Ferrous

Single20 Grams to 200 Kg. for Steel & 20 Grams To 40 Kg for Non – Ferrous | Description | Capabilities |

|---|---|

| Area of Land | 4800 Sq. Mt. |

| Built Up Area | 1600 Sq. Mt. |

| Production Capacity | 100 Mt. / Month |

| Present Capacity | 25 Mt. / Month |

| Max Product Size | 700mm x 800mm |

| Weight Range | 20 Grams to 200 Kg |

| Min. Wall Thickness | 3mm |

| Surface Roughness (Steel) | As Cast Ra 3.2 To 6.3 µm, Machined Ra. ,04 µm |

| Surface Rought (Non-Ferrous) | - |

| Quality Certificates | ISO 9001:2015 |

| Total Employees | 60 People |

In house spectrometer with 36 Elements capable of testing Fe, Ni, Co based materials and also Nitrogen content.

In house spectrometer with 36 Elements capable of testing Fe, Ni, Co based materials and also Nitrogen content.

All heats poured are tested on-line on Spectrometer.

All heats poured are tested on-line on Spectrometer.

All the scrap used are also tested before using.

All the scrap used are also tested before using.

Specimens are stored for particular period.

Specimens are stored for particular period.